Die Casting Vs. Sand Casting: Who Is The Winner?

- nbtenact

- Jan 3, 2024

- 4 min read

Cue the dramatic music because we're about to unravel the ultimate showdown in metal casting. Picture molten metal as the diva and two contenders—die casting and sand casting—eager to be her dance partner. Get ready for a journey through the dazzling precision pirouettes, the lightning-fast twirls, and the jaw-dropping performance that makes die-casting the undisputed star of this industrial ballet.

Die Casting: Precision Dance Extravaganza

The Precision Waltz

Imagine the precision of a prima ballerina – that's die-casting in a nutshell. It's not just metal being poured into a mold; it's a meticulously choreographed waltz, with molten metal swirling into a precisely crafted steel mold, hitting every beat with accuracy that would make any choreographer jealous.

Turbo-Charged Tango: Speed Unleashed

Die casting isn't satisfied with a slow dance; it's a turbo-charged tango of efficiency. The high-pressure injection? That dance move fills the mold at the speed of a metal hurricane, creating a performance with shorter cycle times that even the Flash would envy.

Metal Maestros: The Materials Lineup

In this dance-off, we've got a lineup of metal maestros – aluminum, zinc, and magnesium – each ready to steal the show. They're not just metals; they're dance partners with the fluidity to nail those intricate moves, creating a visually stunning spectacle.

Aesthetic Fireworks: The Finale

As the curtain falls, get ready for the aesthetic fireworks. Die casting doesn't just stop at precision; it's a sensory feast. Smooth surfaces beckon to be touched, sharp edges demand attention, and intricate details create a visual crescendo that's more art than industrial process.

Applause-Worthy Applications

Automotive Blitz: From engine components to vehicle interiors, die casting takes the lead in the automotive world, creating components that are the real rockstars of the road.

Electronics Extravaganza: In the electronics realm, die casting crafts the casings for gadgets, ensuring every device gets its moment in the spotlight with precision and style.

Aerospace Spectacle: The aerospace industry witnesses a spectacular performance as die-casting crafts lightweight yet robust components, ensuring that airplanes soar to new heights.

Sand Casting: The Artisan's Bohemian Rhapsody

Craftsmanship Unleashed

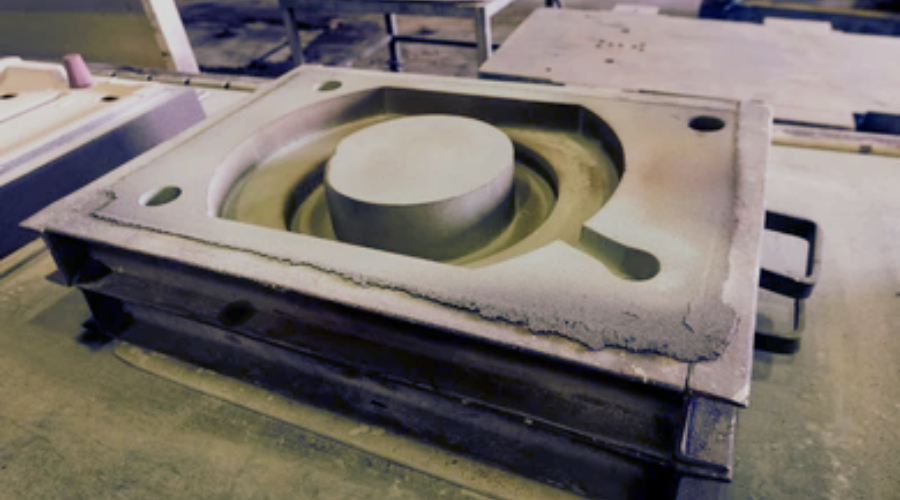

Switching gears to sand casting is not just a dance; it's a bohemian rhapsody of craftsmanship. Molds created from compacted sand offer a touch of artistry, a rebellion against the rigidity of traditional industrial performances.

Versatility in Every Step

The traditional dance steps don't bind sand casting. It's a freedom tango where molds can be altered with the ease of a seasoned dancer, allowing for the creation of intricate and irregular designs. It's the dance routine for those seeking a customized performance.

Melting Pot Symphony

In this dance, alloys from both ends of the spectrum join the melting pot symphony. Ferrous and non-ferrous metals meld into an alchemical dance, expanding the possibilities for manufacturers and creating a dance floor that welcomes all.

Budget-Friendly Ballet

Sand casting takes the spotlight for its budget-friendly ballet as the music shifts. The simplicity of materials and the dance steps of the casting process result in reduced tooling costs, making it the Cinderella of the casting world, accessible to all.

Applications: Where Artistry and Industry Tango

Sculptural Serenade: Sand casting shines in a serenade, crafting unique and artistic metal sculptures that dance to their beat, celebrating individuality.

Heavy Machinery Waltz: Sand casting leads the waltz in producing large and robust components for heavy machinery, a dance that marries strength with customization.

Prototyping Pas de Deux: The ballet concludes with a prototyping pas de deux, where sand casting becomes the ideal partner for experimental designs, offering a playground for innovation without breaking the bank.

Die Casting vs. sand Casting an overview:

Characteristic | Die Casting | Sand Casting | |

Dimensional Accuracy | Very high | Medium/low | |

Required Lead Time | 6-10 weeks | 1-2 weeks | |

Surface Finish Out of Mold | Excellent | Granular/poor | |

Complexity of Parts | Very high | High | |

Preferred Production Volume | 1000+ castings | 1-1000 castings | |

Price | High | Low |

Nbtenact

Nbtenact is a reliable manufacturer and supplier of custom die casting parts in China. Our parts are the epitome of flawless finishing, precision, and durability. Place your order with the trusted custom die casting parts exporter and get these fantastic parts at an affordable price range.

FAQs: Backstage Pass to the Casting Chronicles

Q1: Can sand casting sway to the same precision rhythm as die casting?

A1: Sand casting has its rhythm, embracing craftsmanship and versatility, but it's not the precision maestro that die casting is.

Q2: Does the die-casting performance come with a higher ticket price than sand casting?

A2: Initially, die casting might demand a grand entrance fee due to tooling costs, but its efficiency in mass production often balances out the overall expenses

.

Q3: Which method leads to the dance of prototyping new designs?

A3: Sand casting takes the lead in prototyping and twirling with cost-effectiveness and flexibility in altering molds for experimental designs.

Q4: Are there limitations to the materials allowed in the die-casting dance?

A4: Die casting primarily invites non-ferrous metals to join its dance, showcasing superior fluidity but limiting the material choices compared to the eclectic dance floor of sand casting.

Conclusion: The Encore of Die Casting

As the curtain falls on this casting extravaganza, die casting emerges as the rockstar, the diva, the virtuoso of the metal ballet. It's not just about shaping metal; it's about conducting a show-stopping masterpiece in efficiency, precision, and industrial artistry. The applause echoes through industries, from automotive to aerospace, leaving an indelible mark on the casting stage. The encore belongs to die casting, the true headliner of this thrilling metal dance-off!

Comments