What is the process of die-casting?

- nbtenact

- Dec 28, 2023

- 3 min read

Explore the die-casting process, where precision and artistry meet in fabricating intricate components. This detailed tutorial will take you through the entire die-casting process, from mold preparation to the last finishing touches.

Unveiling the Die Casting Process

Die casting, a complex and precise manufacturing method, unfolds through multiple stages, each demanding meticulous attention.

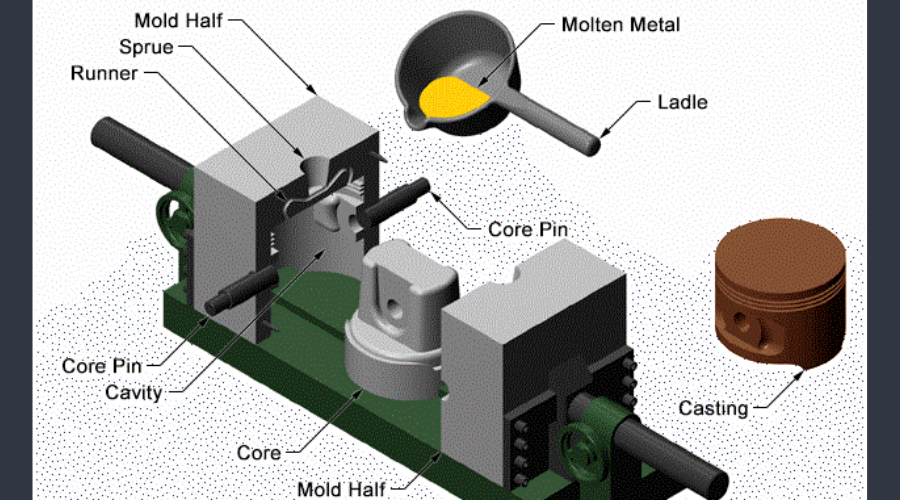

1. Meticulous Mold Preparation

The die-casting journey commences with the careful preparation of molds. Crafted from high-quality steel, these molds undergo a meticulous design process that ensures they align flawlessly with product specifications. This step is crucial in creating a canvas that captures every minute detail with precision.

2. The Metamorphosis: Melting the Metal

The chosen metal, typically aluminum or zinc, undergoes a transformative journey from solid to liquid in the crucible furnace. This molten metal cauldron becomes the raw material for the intricate casting process. The selection of the metal alloy is a critical decision, with each alloy offering distinct advantages in strength, durability, and heat resistance.

3. Injection Precision and High-Pressure Drama

With molten metal ready, the injection into the mold becomes a symphony of precision and speed. High pressure ensures a seamless mold filling, capturing even the most intricate design elements. This stage demands a delicate balance of temperature control and pressure management to prevent defects and ensure uniformity in the finished product.

4. Controlled Cooling and Solidification

A controlled cooling system swoops in as molten metal forms within the mold. This process solidifies the metal, locking in the design intricacies. The cooling phase is a critical step in achieving the desired microstructure, which influences the mechanical properties of the final product. The cooling rate is carefully controlled to prevent internal stresses and ensure optimal material properties.

5. The Grand Reveal: Ejection and Finishing

The mold opens to reveal the freshly cast component. Ejection is a phase where precision is paramount to avoid damage. Subsequently, the component undergoes meticulous finishing processes, including trimming, machining, and surface treatment, to meet specified requirements. Post-casting therapies, such as heat treatment, may be employed to enhance the component's mechanical properties and overall performance.

Nbtenact

Nbtenact is a renowned manufacturer and supplier of vehicle and industrial machine parts. Our products are famous for their precision, flawless finish, and sturdiness. Place your order with the reliable custom die casting parts exporter and get these fantastic parts at discounted rates.

FAQs: Decoding the Mysteries of Die Casting

Q1: Which metals are commonly used in die casting?

A1: Primary metals include aluminum and zinc due to their favorable characteristics—high thermal conductivity, low melting points, and excellent fluidity. However, other alloys like magnesium and copper are also utilized for specific applications.

Q2: How is mold quality ensured?

A2: Advanced technologies like computer-aided design (CAD) and computer-aided manufacturing (CAM) ensure precise molds. Rigorous testing and quality control measures guarantee accuracy. Additionally, periodic maintenance and refurbishment of molds are carried out to ensure longevity and consistency in production.

Q3: Can die casting be used for mass production?

A3: Absolutely! Die casting excels in producing large quantities with consistent quality, which is why it is ideal for mass production in various industries. The high speed and efficiency of the process contribute to cost-effectiveness in large-scale manufacturing.

Q4: Are there limitations to die casting?

A4: While excellent for complex shapes, designs with fragile walls or intricate details may pose challenges. Engineers collaborate with designers to find suitable alternatives, such as design modifications or additional post-casting processes, to address these limitations. Die casting is a versatile process, and advancements continue to push the boundaries of what is achievable.

Conclusion: Crafting Excellence through Die Casting Mastery

In the symphony of manufacturing, die casting is a testament to human ingenuity and the pursuit of perfection. As technology advances, this intricate process continues to shape the world with its strength and precision. The art of die casting, from meticulous mold preparation to the final finishing touches and beyond, epitomizes craftsmanship in every molten metal dance—a masterpiece ready to serve diverse industries with unparalleled precision and durability.

Comentários